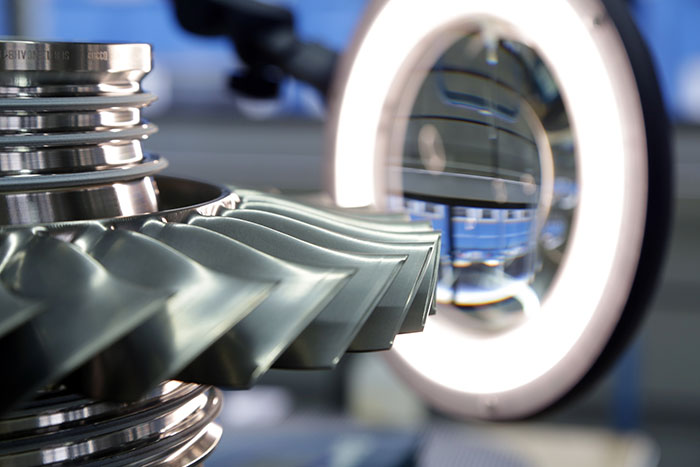

MTU has been impressively shaping aviation for decades and has always been a technology pacesetter.

Today, too, we remain committed to finding answers to the challenges of tomorrow: commercial engines must become even more fuel-efficient and environmentally sustainable—and ultimately emissions-free—and military engines even more powerful.

Never before have we had such forward-looking concepts as we do today.