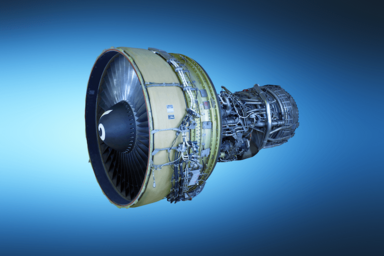

Whether it’s the PW1100G-JM from the GTF engine family for the A320neo, the GE9X that powers the new Boeing 777X long-haul aircraft, or the PW800 for the Dassault Falcon 6X—MTU Aero Engines components are found in one-third of the world’s commercial aircraft. In addition to key components such as high-pressure compressors and low-pressure turbines, MTU develops and manufactures numerous other engine parts, including turbine center frames and additively manufactured borescope bosses. As the industrial lead company for the German Armed Forces, MTU has been involved in crucial military engine programs for decades. The company is also lending its expertise to future projects, such as the New Generation Fighter Engine (NGFE).

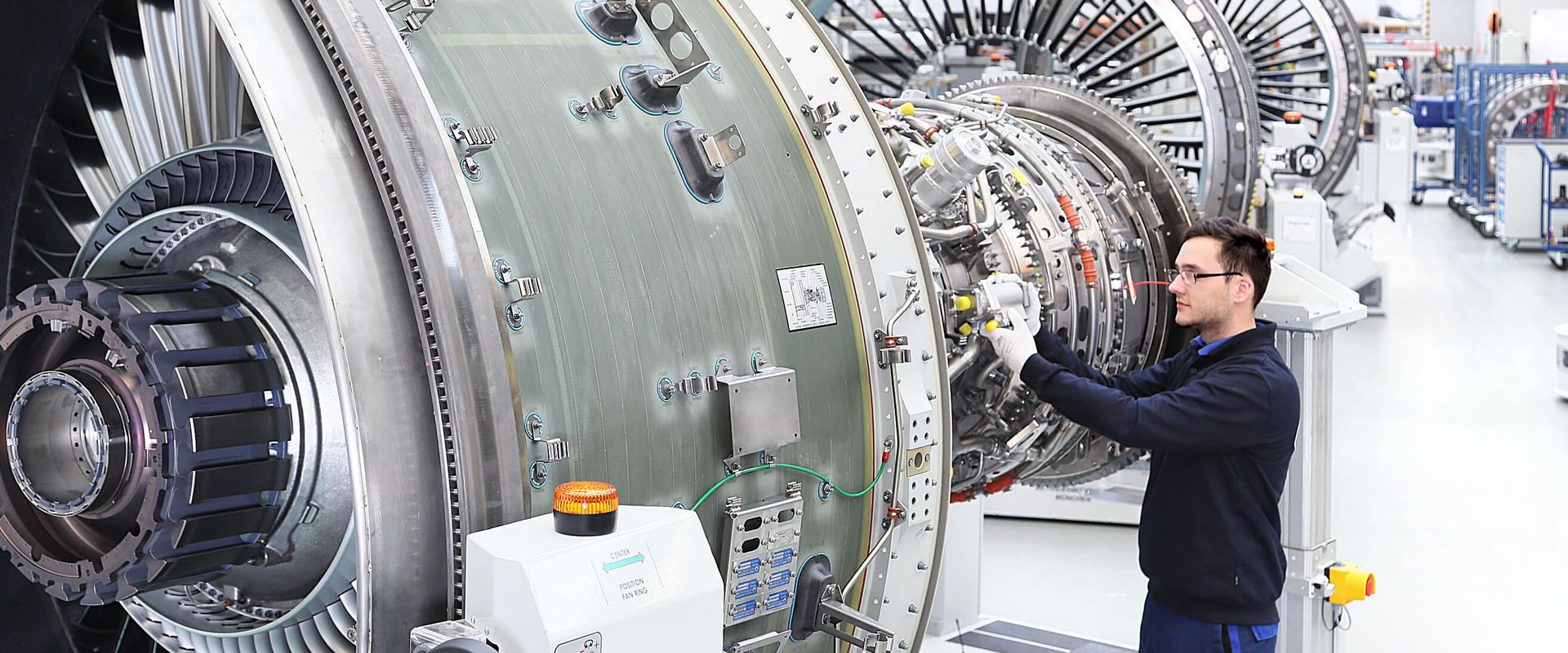

But MTU’s engine know-how extends well beyond the OEM business. With more than 270 airline customers and a portfolio covering over 30 engine types, in terms of revenue MTU Maintenance is the world’s largest independent MRO provider for commercial engines.