MTU Maintenance Hannover

MTU Maintenance Hannover GmbH

MTU Maintenance Hannover’s founding in 1979 marked MTU’s first foray into commercial engine maintenance. It has since been the centerpiece of MTU Maintenance and is the most experienced site in the network. The facility boasts a workforce of over 2,500 engine experts, who perform approximately 400 shop visits per year. In 2023, the location reached 10,000 total shop visits in its operational history.

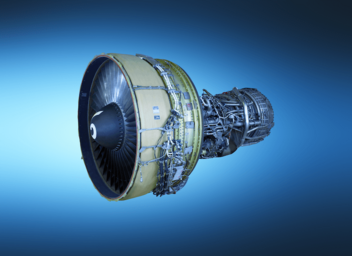

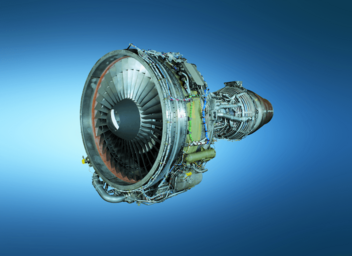

MTU Maintenance Hannover’s engine MRO portfolio consists of medium-sized and large commercial engines such as GE's CF6-80C2, GE90-110/-115B and GEnx engines, as well as Pratt & Whitney’s PW1100G-JM and PW2000 engines. In addition, it services IAE's V2500 engine. The location prides itself as MTU’s center of excellence for high-tech repairs and continually develops new repair techniques and processes.

In 2022, the Hannover site completed the expansion of an additional workshop for engine maintenance measuring 27,000 square meters and a brand-new, modern building with 6,900 square meters of office space.

Interested in our environmental statement?

Contact

30855 Langenhagen

Germany

Are you interested in starting your career at MTU Maintenance Hannover?