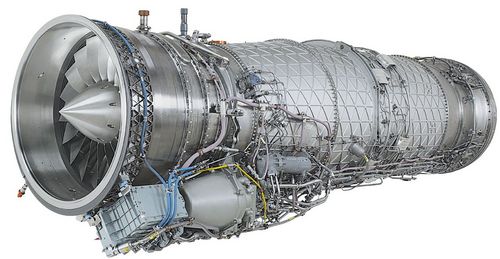

EJ200

EJ200: Powering the Eurofighter

The EJ200 is the result of a European consortium (EUROJET Turbo GmbH) comprising MTU, Rolls-Royce, Avio Aero, and ITP Aero. Providing 20,000 pounds of thrust, it is one of the most advanced engines in its class and powers the Eurofighter and its export version, the Typhoon.

MTU’s involvement in the EJ200

With a production share of 30 percent, MTU plays a major role in the Eurofighter engine. MTU is responsible for developing and manufacturing the low- and high-pressure compressors as well as the digital engine control and monitoring unit (DECMU) for all engines operated by the German Air Force, its partners, and for export customers. The company is also responsible for final assembly, testing, and repair of the engines operated by the German Air Force and the Austrian Armed Forces.

It was for the EJ200 that MTU first developed compressor stages in blisk (blade integrated disk) design; these are now used in commercial engines as well. MTU has also established itself as one of the world’s leading manufacturers of blisk technology. At its Munich site, the company operates an advanced production system for compressor rotors for commercial engines.

Facts

- EIS: 2003

- The EJ200 is a two-shaft turbofan engine with afterburner in the thrust category 20,000 lbf

- Modular design (15 fully interchangeable modules)

- Low-pressure compressors with 3 stages in blisk design

- High pressure compressors with 5 stages partly in blisk design (3 stages blisk, 2 stages conventional)

- Single-crystal turbine blades

- Convergent/divergent nozzle

- Digital control with integrated health monitoring and life cycle monitoring

- On-condition maintenance concept

MTU competencies

- 33% Development

- 30% Manufacture

- Development and manufacture of low-pressure compressor, high-pressure compressor and Digital Engine Control and Monitoring Unit (DECMU)

- Final assembly of EJ200 engines for the German Air Force and for the Austrian Armed Forces

- Maintenance in cooperation with the German Armed Forces at MTU Aero Engines in Munich/Erding

Application

- Eurofighter / Typhoon

Partners

- Rolls-Royce

- Avio Aero

- ITP Aero

Technical Data

| Max. thrust with afterburner | 20,000 lbf |

| Max. thrust without afterburner | 13,500 lbf |

| Pressure ratio | 26:1 |

| Bypass ratio | 0.4:1 |

| Length | appr. 13.1 ft |

| Weight | appr. 2,204 lbs |