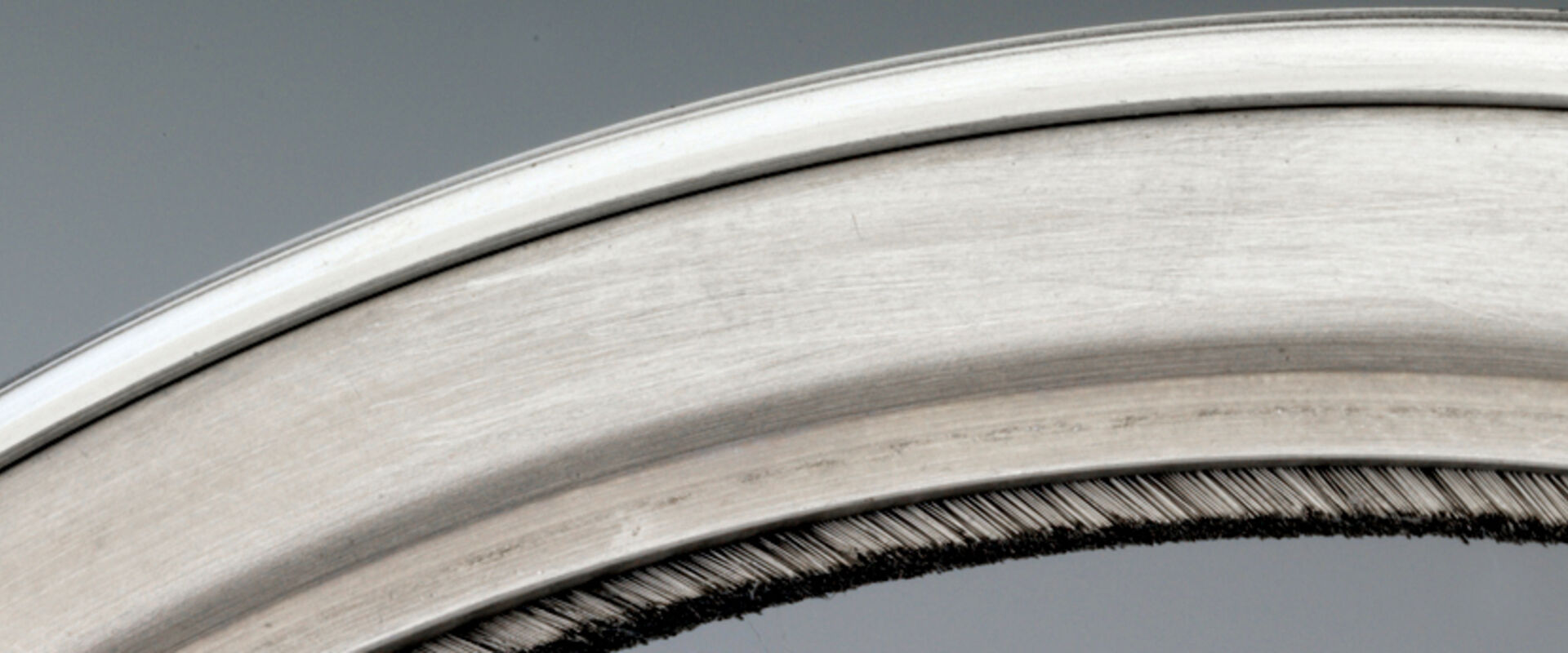

Thanks to their unique manufacturing process MTU brush seals are highly efficient and very easy to install. They clearly outperform conventional sealing systems, such as labyrinth seals: MTU brush seals reduce leakages by up to 90 percent thus enhancing the efficiency of engines or gas turbines and help markedly lower operating costs.

Benefits afforded by MTU brush seals:

- Up to 90 percent less leakage and, as a result, enhanced efficiency

- Compact design

- Stable operating behavior

- Long service life

- Ease of maintenance and replacement

- Suitable for a variety of applications

- Usable under the most extreme operating conditions

MTU Aero Engines has been developing, manufacturing and marketing these innovative seals for over three decades. MTU brush seals are suitable for use in aircraft engines and industrial applications. MTU has become a global leader in this area and offers its customers comprehensive services, from development and manufacture all the way through to on-site support.

For further inquiries please use our contact form