Sales Contact

Europe & Africa

South and North America

Far East

Middle East & Southeast Asia

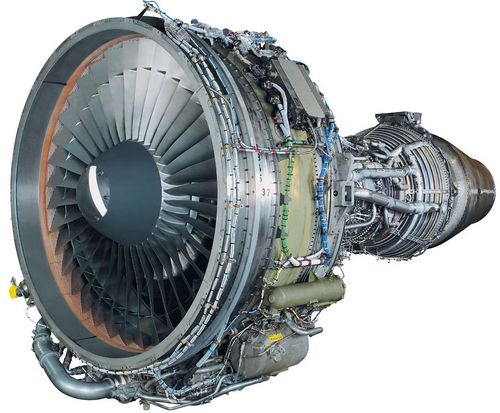

Since 1979, MTU has developed and manufactured components for the PW2000 engine family, as a partner of Pratt & Whitney. PW2000 engines are in use in medium- to long-haul commercial and military aircraft.

MTU holds a 21.2-percent stake in this successful engine, having developed the low-pressure turbine and turbine exit casing as well as key components for the low-pressure turbine and other highly-engineered components. The PW2000 is the first commercial low-pressure turbine developed under MTU's own responsibility.

MTU Maintenance Hannover in turn provides full repair services for the engine.

| Max. thrust | 43,000 lbf | |

| Bypass ratio | 6:1 | |

| Pressure ratio | 30:1 | |

| Length | 141 in | |

| Fan diameter | 79 in | |

| Weight | 7,299 lbs | |