MTU @ Paris Air Show 2025

Passion for Engines—under this motto, MTU Aero Engines will present itself at the Paris Air Show from June 16 to 22. This passion goes beyond technological excellence: it reflects a firm commitment to responsibility. Responsibility for Europe's defense sovereignty. For ecological sustainability. For safe aviation. For our employees. And for a prosperous economic future.

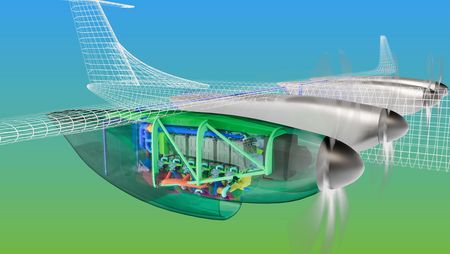

At Hall 2A, Booth C254, we will showcase how our innovative propulsion technologies provide answers to the challenges of our time—from evolutionary advancements of the geared turbofan to revolutionary concepts like the Flying Fuel Cell™. An interactive turbofan model will illustrate our cutting-edge compressor and turbine technologies. The technology display is complemented by the Clean Sky 2 demonstrator EMVAL, which validates new low-pressure turbine technologies, as well as a showcase featuring component innovations.

We are also setting new standards in military aviation: with the Eurofighter EJ200 engine, a mock-up of the New Generation Fighter Engine, and a propulsion model for the next generation of European helicopters. Augmented reality brings our military expertise to life.

Another highlight: our customized maintenance solutions, which ensure flight safety around the globe—presented through an interactive holo-touch exhibit and a display case with V2500 repair samples.

MTU stands for over 90 years of aviation expertise—and for a future we are actively helping to shape. As a reliable partner of the German Armed Forces, as a driver of innovation for sustainable and safe aviation, and as an attractive employer for over 13,000 employees worldwide. Together, we take responsibility5today, tomorrow, and for decades to come.

Driven by responsibility

“Responsibility may be a difficult word, but for us, it’s a promise that we at MTU live by with full conviction. It means developing propulsion technologies that pave the way to sustainable aviation. We do our part for the safety of global air traffic by offering the highest quality. But for us, responsibility doesn’t end at the factory gate: we stand up for our values and for a free, democratic way of life. Our expertise in the field of military propulsion systems strengthens national security and European sovereignty. We take responsibility—for our employees, for sustainable growth worldwide, and for entrepreneurial activity that creates opportunities.”

Lars Wagner, CEO, MTU Aero Engines AG

MTU stories around the trade fair

The most powerful engine of the world

The GE9X engine from GE Aerospace will power the new Boeing 777X widebody aircraft. At rollout this will be the world’s largest and most powerful commercial engine. MTU has a 4 percent share in the GE9X program, with responsibility for developing and manufacturing the turbine center frame.

Michael Vos, Director GE Programs at MTU, is presenting the engine at the Paris Air Show 2025.

High-tech for the air force of tomorrow

The New Generation Fighter Engine (NGFE) sets new standards for sixth-generation fighter jets. As the heart of the New Generation Fighter, part of Europe’s Future Combat Air System (FCAS), it combines maximum efficiency, innovative hybrid technologies, and extreme performance. We contribute our expertise in key areas such as compressor technology and engine control—for the ultimate in power, maneuverability, and availability on every mission.

MTU News around the trade fair

Discover the highlights at our booth

Come aboard!

There are over 13,000 of us. At 19 locations worldwide. One in three aircraft flies with our technology. And we work every day to make it even more. Even better. Even more powerful. Even more sustainable. That’s why we employ the best the world has to offer. Join us to enjoy exciting work, excellent career prospects, and one-of-a-kind team spirit. Together we will shape the future of aviation.