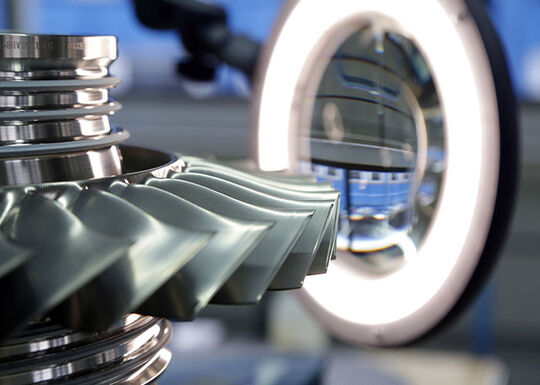

As a high-tech company, we are recognized around the globe for our advanced engine technologies. Our tremendous innovative strength is attested to by the over 200 patent applications and invention disclosures we file every year. We’ve been setting the pace in the aviation industry for decades and are constantly pushing the boundaries of what’s possible. We do this together with our partners: an excellent network of industry, universities, and research institutes. Together, we’re constantly finding successful new technologies and propulsion concepts to transform aviation into a more sustainable industry. Our focus here is on further developing our core competencies—high-pressure compressors, low-pressure turbines, and turbine center frames—as well as cutting-edge, automated manufacturing and repair processes.

High tech for the air force of tomorrow

The New Generation Fighter Engine (NGFE) sets new standards for sixth-generation fighter jets. As the heart of the New Generation Fighter, part of Europe’s Future Combat Air System (FCAS), it combines maximum efficiency, innovative hybrid technologies, and extreme performance. We contribute our expertise in key areas such as compressor technology and engine control—for the ultimate in power, maneuverability, and availability on every mission. We’re also thinking ahead for Europe’s military helicopters: together with Safran and Avio Aero, we’re collaborating on innovative propulsion solutions for tomorrow.

Here you can find out what innovative technologies are in development for the NGFE:

New Generation Fighter Engine

The virtual engine

By using digital twins, we aim to map the entire lifecycle of an engine in the virtual space—starting with the first design sketch, continuing on to manufacturing, and ultimately to daily use above the clouds. This enables us to detect deviations at an early stage, increase efficiency, and carry out predictive maintenance. As a result, we can save time, reduce costs, and ensure even greater reliability in aviation. You can find out exactly how this works here:

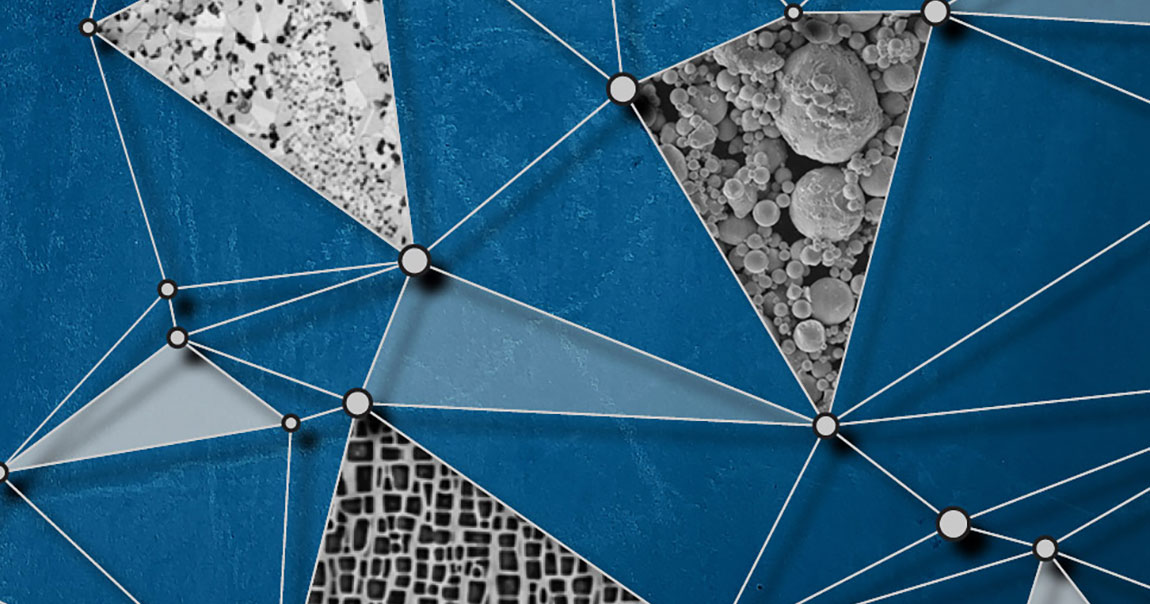

High-performance materials for the engines of the future

Any new materials or coatings for engines of the future have to be lightweight, extremely resistant to heat, and robust. We focus on the best material classes, such as single crystals, high-temperature-resistant disk materials, materials for additively manufactured components, and specific protective coatings. More and more, we’re looking at materials that are new to us as an engine manufacturer. Functional materials with specific electrical, chemical, magnetic, and catalytic properties play a decisive role in our revolutionary Flying Fuel Cell™ propulsion concept. Together with our partners, we’re optimizing and qualifying these materials in terms of their properties and means of manufacture.

A strong research network

Groundbreaking technologies require visionary ideas and regular injections of fresh momentum. For this we turn to our strong network of industry and research partners. The focus is on basic research at selected leading institutes, trend research, and the development of visionary engine concepts at Bauhaus Luftfahrt as well as exchange with experts across industries. We’re involved in the top research projects at the German and European levels, such as Germany’s Federal Aviation Research Program (LuFo), technology development for the German Federal Ministry of Defence, and the EU’s Clean Aviation. Sustained, long-term public funding is a key pillar for the successful development of innovative technologies at MTU. As we drive aviation technology forward, we rely on a new generation of skilled employees. To that end, we promote exchange and collaboration with young and talented individuals.