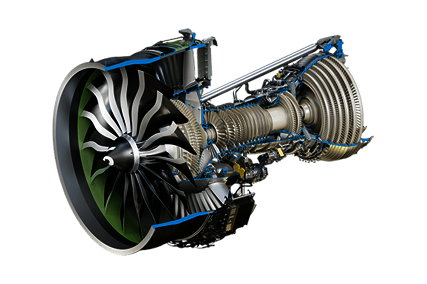

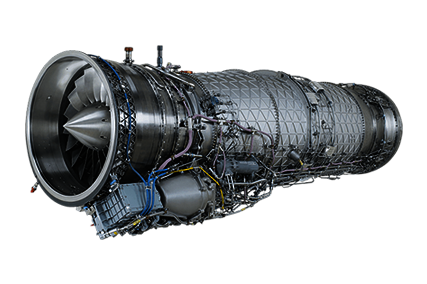

Commercial aircraft move people and freight from one continent to another in a matter of hours. Having powerful, reliable engines is essential for smooth fleet operations. MTU Aero Engines is a partner in numerous pioneering commercial engine programs for all aircraft size classes operating on short- to medium- to long-haul routes. In the commercial OEM business, the company plays a key role in developing, manufacturing and marketing high-tech components such as high-pressure compressors, low-pressure turbines and turbine center frames. Around one-third of all aircraft in service worldwide today have MTU components on board.

However, the Group’s activities extend beyond the OEM business: in terms of revenue, MTU Maintenance is the world’s largest independent MRO provider for commercial engines.