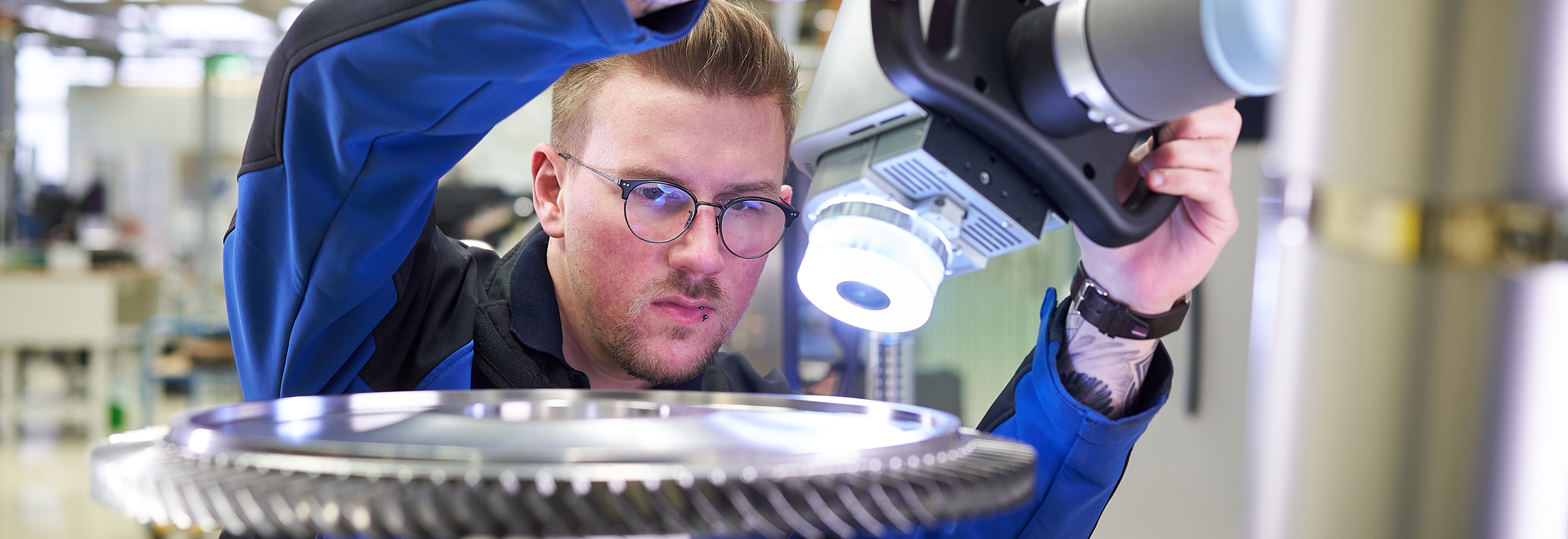

Quality and Safety

In aviation, where the smallest of mistakes may have catastrophic consequences, safety is a prime concern. MTU Aero Engines insists on the finest quality for its products and services. Quality spells safety, and safety is the first priority in whatever we do.

MTU Aero Engines strictly monitors compliance with its ambitious quality standards at all times and across all levels of production and personnel. Its management system ensures the company observes all applicable legal and statutory regulations and clearly defines roles and responsibilities in the company. This enables MTU Aero Engines to promise its customers the same level of quality they have a right to expect at any of the company's locations worldwide. Compliance with quality requirements is verified by government agencies and through internal and external audits.