History

1913The nucleus

MTU no doubt had its origin in the aircraft engine factory founded in 1913 by Karl Rapp at Munich's Oberwiesenfeld.

1917Bayerische Motorenwerke (BMW) launched

In 1917, Rapp Motorenwerke became Bayerische Motorenwerke (BMW) from which in 1934 a spin-off emerged, BMW Flugmotorenbau GmbH, a milestone in the history of MTU.

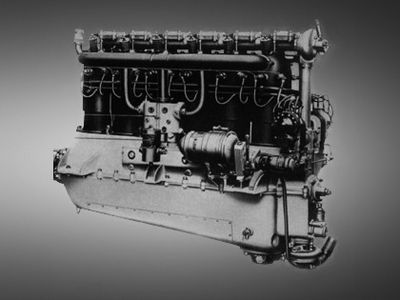

1918BMW Illa – the "Bavarian engine"

Founded in 1917, BMW rapidly grew to become the world's third-largest engine maker, with 3,500 personnel earning their bread and butter at its Munich facility. In 1918 they started manufacturing the BMW Illa engine, which also became known as the "Bavarian engine". BMW had emerged in 1917 from the Munich-based Rapp Motorenwerke GmbH.

1925Daimler and Benz: aircraft engine expertise

From the very beginning, Daimler and Benz played a significant part in the development and production of aircraft engines. After Daimler equipped the zeppelin LZ1 airship with its engines, the company in 1925 began developing its DB 600, a landmark engine whose basic design continued through subsequent generations of Daimler-Benz aircraft engines. It was this know-how of Daimler-Benz AG, Germany's leading engine manufacturer in the 1940's, that largely helped the later MTU gain the leadership position it now enjoys.

1926The Daimler-Benz merger

After the conclusion of World War I, aircraft engine production suffered under the constraints imposed by the Versailles Treaty. Engine makers were therefore compelled to diversify their product lines. Simultaneously, the need to cooperate became increasingly apparent. In 1926, Daimler and Benz merged, laying the foundation of a uniquely successful corporate history. BMW in turn collaborated closely with Pratt & Whitney and when the dictates of the Versailles Treaty were lifted, vigorously returned to aircraft engine making.

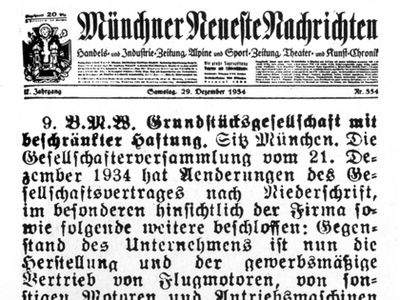

1934Launch of BMW Flugmotoren GmbH

On December 22, 1934, BMW AG divested its BMW Flugmotorenbau GmbH in an attempt to duck the growing pressure the Nazis exerted also on this sector of the production history.

1936Manufacturing aircraft engines at Allach

BMW Flugmotorenbau GmbH in 1936 moved into the new factory it had built at Allach on the outskirts of Munich. This is where the MTU Aero Engines is located today.

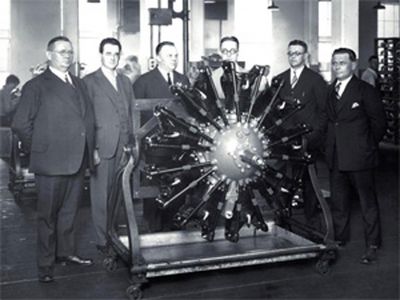

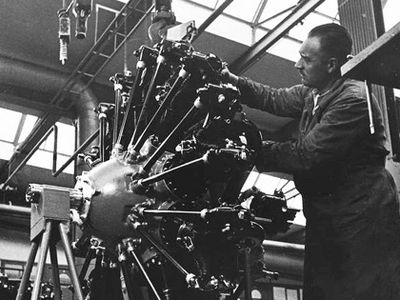

1940Large-scale production in Munich-Allach

With the BMW 801, BMW Flugmotorenbau GmbH developed the first German twin-row radial engine. With the Nazi regime’s ever-expanding military build-up and the subsequent war, during which the BMW 801 found extensive use as the powerplant for a number of fighter aircraft, among them the Focke-Wulf Fw190, the company pushed the speed of development and the scale of production to the limits of its capacity. Sadly it even went far beyond, especially towards the end of the war, when thousands of forced laborers had to work at the plant to further increase its output. After just two years of development, the first engines were delivered in 1940, and production — which mainly took place in Munich-Allach — was ramped up to around 1,000 units per month by early 1944. In all, the company produced some 30,000 BMW 801s.

1943Forced labor in engine construction

Between 1940 and 1945, several thousand foreign and forced laborers, concentration camp prisoners from over 25 nations and Russian prisoners of war were forced to work at the Munich-Allach site. They lived under terrible conditions in neighboring forced labor camps and quarters. In addition, a sub-camp of the Dachau concentration camp was built in Allach in 1943. Their inhuman toil and suffering in wartime production have not been forgotten: Starting in 1999, MTU and the BMW Group had this chapter of the company's history extensively researched and scientifically reviewed in two dissertations as part of the "Remembering Together" ("Gemeinsam Erinnern") project. Further information is available on the website of the BMW Group.

Picture: BMW Group Historisches Dokumentationszentrum

1945The post-war era

At the conclusion of World War II, the production of aircraft engines was halted when the factory was occupied by U.S. troops. It was largely spared the fate of dismantling, not uncommon at the time, and did not build any more aircraft engines until much later, in 1955.

1954A new beginning

The shift in the German political landscape (air sovereignty, rearmament) put the issue of aircraft and aircraft engine production back on the agenda. In this context, the launch of BMW Studiengesellschaft on January 22, 1954, marked a new beginning and return, if ever so modest, to aircraft engine development on the northern outskirts of Munich. It also signaled another step forward on the route to today's MTU.

1955Repair depot for U.S. Army vehicles and artillery

After U.S. troops had occupied the factory, they turned the BMW-Flugmotorenwerk into a shop that repaired Army vehicles and artillery of all types sent there from all over Europe.

1957Launch of BMW Triebwerkbau GmbH

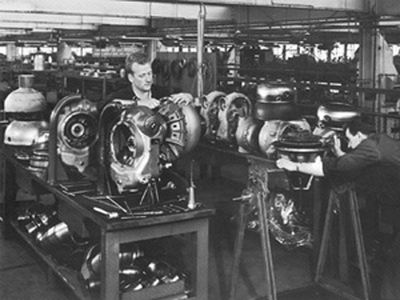

In 1957, BMW founded BMW Triebwerkbau GmbH in Allach to resume engine production under license agreements. It started out overhauling U.S.-made engines and then began assembling U.S.-made components.

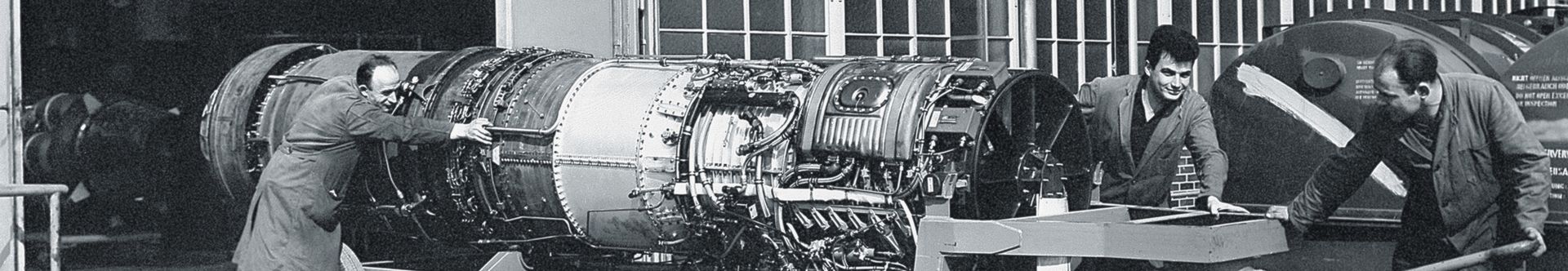

1959License manufacture of J79 engine powering the Starfighter aircraft

In the German armed forces' second procurement phase, the company began in 1959 to produce J79-11A engines under license from GE. These engines powered the Lockheed F-104 Starfighter.

196050% stake

In 1960, MAN acquired a 50% stake in BMW Triebwerkbau GmbH.

1965Merger to create M.A.N. Turbo GmbH

After M.A.N. had acquired a 50% role in BMW Triebwerkbau GmbH back in 1960, that company merged with M.A.N. Turbomotoren GmbH in 1965 to form M.A.N., with BMW shedding its aircraft engine activities. The new company additionally won orders for the license production of engines powering the Breguet Atlantic reconnaissance and anti-submarine warfare aircraft and the military C-160 Transall transport.

1969A new chapter: MTU is founded

1969 was the year when mankind realized an old dream – that of setting foot on the moon and returning safely to earth. That same year, the engine activities of Daimler-Benz and M.A.N. were joined on July 11 to form MTU Motoren- und Turbinen-Union München GmbH M.A.N. Maybach Mercedes-Benz. It was not as much a launch of a completely new company as the consolidation of Daimler-Benz' heavy-duty diesel engine activities with M.A.N.'s turbine engine activities. The newly founded MTU group included MTU München (aircraft engines) and MTU Friedrichshafen (diesel engines) with a combined workforce of almost 11,000 at the time.

1969Success story in the 1970s: the Tornado

1969 also was the year when development of an engine began that turned out be MTU's most successful engine program ever, the RB199-34R powering the Tornado multirole combat aircraft. To develop that engine, MTU, Rolls-Royce and FiatAvio had formed a joint company, Turbo-Union Ltd. which in October 1969 won the production contract for the RB199 engine.

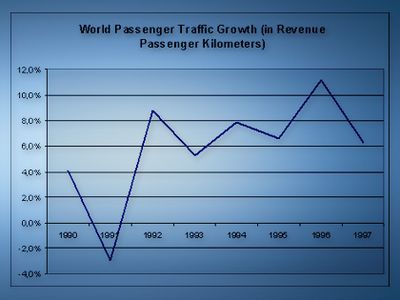

1971Invading the commercial engine market

In the 1970s, development of commercial engines began playing an even more significant part in the company's activities that had been focused almost entirely on military business. After M.A.N. Turbo, MTU's precursor, had previously made forays into the commercial engine sector, MTU began to methodically expand these efforts. In 1971, a cooperation agreement was signed with GE that gave MTU a manufacturing role in the CF6-50 engine powering the Airbus A300.

1979Demand-driven diversification

Growing demand for engine maintenance, repair and overhaul (MRO) services caused MTU in 1979 to form MTU Maintenance Hannover, at Langenhagen and separate its MRO activities from the manufacturing activities in Munich. And as MRO demand continued to rise, MTU launched another shop, MTU Maintenance Berlin-Brandenburg, at Ludwigsfelde near Berlin in 1991. The early focus of these shops was on maintenance, test runs and worldwide services.

1983MTU takes stake in V2500

IAE (International Aero Engines) is formed to develop and market the V2500 engine. Founding members are MTU Aero Engines, Rolls-Royce, Pratt & Whitney, Japanese Aero Engines Corporation JAEC and FiatAvio. In the 1990s, the Fiat group withdraws from IAE and its stakes are taken over in equal shares by Rolls-Royce and Pratt & Whitney.

1985MTU becomes a wholly-owned Daimler-Benz affiliate

M.A.N. AG sold its 50% stake in the company to Daimler-Benz AG, making MTU a wholly-owned Daimler-Benz company. That same year, MTU and Pratt & Whitney Canada begin cooperating.

1986MTU takes stake in EJ200

In 1986, Eurojet Turbo GmbH is founded by Spain, Italy, Great Britain and the Federal Republic of Germany as a consortium for the development and production of the EJ200 engine for the Eurofighter. Shareholders are MTU Aero Engines, Rolls-Royce, FiatAvio and ITP.

1989Launch of Deutsche Aerospace (DASA)

On May 19, 1989, the MTU group was integrated into the newly established Deutsche Aerospace AG, or Dasa for short, which also comprised parts of AEG as well as Dornier and MBB. This move brought almost all of the German aerospace industry together under one roof. Daimler-Benz had grown into a conglomerate that manufactured engines, vehicles and aerospace equipment for transportation on land and sea as well as in air and space. Former Daimler CEO Edzard Reuter's vision of an integrated technology group had become reality.

1989Power for the "Tiger“

The company MTR is founded by MTU, Safran Helicopter Engines and Rolls-Royce. Under the cooperative effort, the MTR390 turboshaft engine, which features a free power turbine, is built. It powers the Franco-German Tiger escort and antitank helicopter. An uprated version, dubbed the MTR390 Enhanced is developed later on by the MTRI consortium for export customers Australia and Spain. MTU's stake in the MTR390 includes the core engine with its combustor and gas generator turbine, plus a number of accessories.

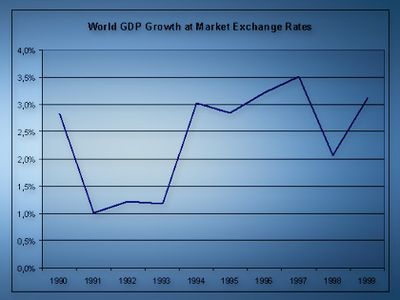

1990Under pressure

Between 1992 and 1995, MTU was hit particularly hard by the turbulence on the world market. A 50 percent drop in orders in the military sector, a simultaneous slump in commercial business and the collapse of the U.S. dollar all put a strain on MTU’s finances. A systematic restructuring program initiated earlier within MTU and strategic additions to the product range formed the basis for the company’s positive development.

1991Launch of MTU Maintenance Berlin-Brandenburg and MTU Maintenance Malaysia

In the 1990's, MTU's MRO activities grew in keeping with rising demand for engine services. It naturally followed that the company launched another repair shop in 1991, this time on the premises of the former state-owned Luftfahrttechnik shop at Germany's Ludwigsfelde, where in the days of the former GDR military engines had been serviced and repaired. This military pattern was continued in the earlier phase of the new MTU shop which initially provided repair services mostly for engines of the German forces.

In November 1991 Airfoil Services was set up as a joint venture between Malaysia Airlines and MTU Maintenance Hannover. Today, Airfoil services is a joint venture between MTU and Lufthansa Technik.

1991Strong with strong partners

To meet the challenges of the global market of the 1990s, the need to enter into strategic alliances and cooperative ventures became increasingly apparent. In 1991, MTU and Pratt & Whitney signed an agreement on a strategic alliance for global cooperation in the commercial turbine engine sector, with the partners agreeing to involve each other as preferred partners in emerging commercial engine programs.

1998MTU participates in the GP7000

GE Aviation and Pratt & Whitney lay down in a letter of intent with Airbus that their joint venture "Engine Alliance" will develop the GP7200 for the world's largest commercial aircraft, the Airbus A380. It is based on GE’s proven GE90 and Pratt & Whitney's PW4000 engines. State-of-the-art technologies have been integrated, making the engine the most environmentally friendly in its class. With a 22.5-percent stake, MTU is the largest partner after GE and Pratt & Whitney and is responsible for the development, manufacture and assembly of the complete low-pressure turbine and the turbine center frame, as well as for the manufacture of high-pressure turbine components.

1998Turnaround

While in 1995 the company's existence was still in serious jeopardy, strategic expansion of the company's portfolio of products and services, precipitated product development, launch of global affiliates (MTU Maintenance Canada in 1998) and sweeping restructuring turned MTU around. Innovative production processes, a rollover of military technology into the commercial sector and participation in long-term technology programs (Engine 3E and others) became the major drivers behind the company's upswing.

1999Globalization

Progressive globalization was marked by the launch of the MTU Aero Engine Design and MTU Maintenance do Brasil Ltda. affiliates.

In 1999, MTU and Honeywell (formerly known as AlliedSignal) founded "Vericor Power Systems" as a 50/50 joint venture. The company, based in Alpharetta (Georgia, U.S.A.), was then taken over in its entirety by MTU in 2002, including all the rights to the TF series of gas turbines.

2000MTU: a directly managed DaimlerChrysler company

When European Aeronautic Defence and Space Company (EADS) was founded in July 2000, MTU became a directly managed DaimlerChrysler affiliate. The reshuffle brought a comprehensive change in the company's corporate identity, turning MTU München into MTU Aero Engines. Its repair shops were renamed MTU Maintenance, plus the name of the respective location (MTU Maintenance Berlin-Brandenburg, etc.).

That same year, MTU Aero Engine Components were launched.

2000Launch of MTU Maintenance Zhuhai

The German engine manufacturer has had presence in China since 2000. By setting up a 50/50 joint venture with China Southern Airlines, China's largest airline, MTU has established a strong foothold in the Asian growth market.

2002Cooperation with the Armed Forces

MTU and the German Armed Forces have been blazing new trails in their cooperation since 2002: To optimize the support of the Eurofighter engine EJ200 they developed the industry-military cooperative model of engine maintenance where the work is performed at a single site: MTU's Munich facility. This saves cost, time and resources and helps the GAF maintain its engine know-how. The model was later expanded to include the RB199, J79, RR250-C20 and MTR390 engines.

2002 Entry into a commercial core engine

Pratt & Whitney's PW6000 is provided with a high-pressure compressor made by MTU Aero Engines. This marks the first time MTU has responsibility for a commercial core engine component. With additional engineering and production stakes in the high-pressure compressor, MTU holds an 18 percent workshare as a risk-and-revenue sharing partner in the program.

2003Major partner in the TP400-D6

As the main German partner in the TP400-D6, the exclusive powerplant for the Airbus A400M military transport, MTU Aero Engines provides high-tech hardware: it is responsible for the entire intermediate-pressure spool and in partnership with France's Safran Aircraft Engines, also contributes the engine control unit. Production testing and delivery is performed exclusively by MTU's Ludwigsfelde location, which has the sole pan-European assembly line for the powerplant.

MTU, Safran Aircraft Engines and Rolls-Royce are the major partners in the TP400-D6 engine consortium Europrop International (EPI), with each of the companies holding 28 percent. The fourth partner is Spain's ITP, which has a program share of 16 percent.

2003Subsidiary renamed MTU Aena

That same year, MTU pools its activities on the U.S. market and merges MTU Aero Engine Design and MTU Aero Engine Components, which now come under the umbrella of MTU Aero Engines North America (MTU AENA).

2004KKR acquires MTU Aero Engines

January 1, 2004: MTU Aero Engines now is a subsidiary of Kohlberg Kravis Roberts (KKR), after DaimlerChrysler sold it the company lock, stock and barrel. KKR, a U.S. private-equity investor, has agreed to keep MTU's strategic alignment and operational business intact, including the company's close partnership with Pratt & Whitney and the involvement of Germany's leading engine manufacturer in current and emerging commercial and military programs.

2005IPO of MTU Aero Engines Holding AG

June 6: The stock of MTU Aero Engines Holding AG is traded on the stock market for the first time, the emission price being 21 €. The stock is more than seven times over-subscribed. The greenshoe option has been fully exercised by June 10. On September 19, 2005 the stock is included in the mid-cap MDAX index.

2006Partner in GE's F414 engine

Under a new risk-and-revenue sharing agreement, MTU acquires a 2.5-percent workshare in GE's F414 fighter aircraft engine, contributing the high-pressure compressor spool and the shrouds for the high-pressure and low-pressure turbines. The move marks the company's foray into the U.S. military market. The F414 powers the U.S. Navy's twin-jet F/A-18 Super Hornet fighter aircraft.

2007Launch of MTU Aero Engines Polska

The youngest scion in MTU's group pf companies is MTU Aero Engines Polska. The company is being set up on a seven hectare plot in Poland's "Aviation Valley". The new foreign affiliate develops and manufactures low-pressure turbine airfoils, assembles LPT modules, and repairs engine parts using high-tech machinery and MTU's innovative repair processes for which the company is renowned worldwide.

2007Technology agenda: Claire I

To make tomorrow's engines quieter and to reduce their fuel consumption and pollutant emissions, the Clean Air Engine (Claire) technology agenda was launched. Here, MTU's key technologies are being combined into a commercial propulsion system that, in the year 2050, will burn 40 percent less fuel, will reduce CO2 emissions by the same amount, and will cut noise by 65 percent. Plans are to achieve the CO2 and noise targets defined by the European aviation industry and research community in the Strategic Research and Innovation Agenda (SRIA) in three stages.

2008MTU takes stakes in the GEnx and the T408 engines

MTU Aero Engine takes on an 18-percent share in the T408 helicopter engine. This is the first time that the company acts as a development participant in a U.S. military engine program. MTU is responsible mainly for the T408's power turbine module; T408 models will be used to power the emerging European Heavy Transport Helicopter (HTH).

MTU also takes 6.6 percent role in GE's GEnx engine, manufacturing the turbine center frame, for which it also assumes development responsibility. The engine powers the Boeing 787 Dreamliner and the Boeing 747-8 long-haul airliner and 747-8 freighter version.

2010 MTU Maintenance obtains a license for the GE90

MTU Maintenance Hannover obtains a license to maintain the GE90-110/115, the world’s most powerful commercial jet engine, expanding the high end of its product offerings. A mere nine months later, the Hannover-based shop has acquired its first three maintenance customers for the huge engine. The two GE90 versions power the Boeing 777, the world’s largest twin-engine airliner.

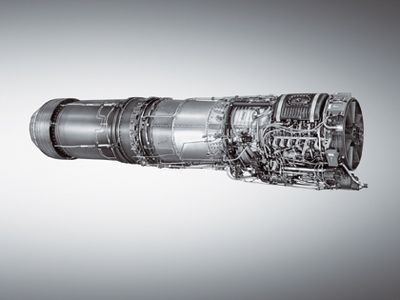

2011MTU takes an 18-percent stake in the PW1100G-JM

MTU Aero Engines takes a program workshare of 18 percent in the Pratt & Whitney GTF PW1100G-JM geared turbofan™* engine. The propulsion system powers the Airbus A320neo family of aircraft. In the PW1100G-JM program, MTU is responsible for the high-speed low-pressure turbine and contributes half of the high-pressure compressor; it will also perform the final assembly of about one third of the engines to be manufactured. With the GTF, Pratt & Whitney and MTU are impressively defining contemporary aviation .

2011Low-pressure turbine sets new standards

Decades of experience have put MTU among the world's technological elite in its core discipline, low-pressure turbines. With its high-speed low-pressure turbine, MTU is now setting new standards in the geared turbofan engines: aerodynamic optimization down to the last detail enables it to achieve higher efficiencies. At the same time, the high rotational speeds that result from the GTF’s reduction gearbox mean the stages work harder. That’s why the pressure turbine module in the A320neo engine needs just three stages.

2011MTU Maintenance Dallas

MTU Maintenance Dallas is MTU’s center of excellence for on-wing and on-site services. In August 2011, MTU Aero Engines has acquired a 75-percent share in former on-wing service specialist Retan Aerospace. The broad engine portfolio includes the CF34, CFM56, V2500, CF6, GE90, PW2000 and PW4000. In October 2013, it moved to an enlarged facility thereby expanding its engine maintenance and associated storage capacity. The company provides rapid response to maintenance needs, whether scheduled or unscheduled. By adding MTU Maintenance Dallas’s expertise to its network, MTU aims to further improve the range of on-wing services for its customer base in the U.S. and the Americas.

2013Technology agenda: Claire II/III

In order to exploit the GTF's full potential, MTU is working on its further development in the next Claire steps: the fan pressure ratio is to be further reduced, thus further increasing the bypass ratio. What sets the GTF propulsion system apart is that it features a reduction gearbox between the fan and low-pressure shaft on which the low-pressure compressor and low-pressure turbine that drives the fan are seated. This increases efficiency and reduces carbon dioxide emissions by 16 percent. By 2030, CO2 emission will be cut by approx. 25 percent and the noise level further reduced as a result of continued optimization.

In the last stage of Claire, major changes are envisaged that may well go beyond today's gas turbine technology. Jointly with universities and other research establishments, MTU is conducting studies for this phase. Among the options under review are the use of highly efficient heat engines with extremely high pressures or the embodiment of recuperative elements to improve the thermodynamic cycle process. Other conceivable concepts include shielded propellers or fans distributed around the fuselage. The goal is achieve a 40-percent reduction in fuel burn by 2050.

2013MTU and Sumitomo Corporation combine competence in engine lease business

MTU Maintenance and Japan-based Sumitomo Corporation, one of the largest trading companies worldwide, have set up two new joint venture companies to jointly expand their commercial aircraft engine lease business.

MTU Maintenance Lease Services B.V., an 80:20 joint venture of MTU Maintenance and Sumitomo Corporation based in Amsterdam, the Netherlands, provides airlines, MRO (maintenance, repair and overhaul) providers and lessors with short- and medium-term lease solutions. SMBC Aero Engine Lease B.V., a 90:10 joint venture of Sumitomo Corporation and MTU Aero Engines, focuses on long-term lease arrangements for its customers.

As part of their cooperation, MTU Maintenance provides Sumitomo Corporation with technical assistance and extensive MRO know-how, especially on engine programs that are part of MTU’s portfolio. These include the CFM56, the V2500, the GE90, the CF34, the CF6, and the PW2000. Moreover, MTU Maintenance contributes its detailed knowledge of future engine programs.

2013Start of additive manufacturing of series components

MTU Aero Engines becomes one of the first companies in the industry to begin manufacturing production components using additive methods. It uses selective laser melting (SLM) at its Munich location to make borescope bosses for the PW1100G-JM engine that powers the A320neo. In this method, the 3D model of the component is “sliced” into individual layers on a computer. Then, using this as a blueprint, the laser melts powdered material to form the component layer by layer on a platform.

2014MTU participates in the GE9X engine for the new “Triple Seven”

When executive officers of GE, MTU Aero Engines, IHI Corporation, Safran Aircraft Engines and Safran Aero Boosters met at the Farnborough International Airshow in mid-July, they signed a contract that heralds a new era in engine history: the partner contract for the GE9X program. The new engine will be the exclusive power plant for Boeing’s 777X long-haul jetliner, which is scheduled to enter service in 2020.

(Photo: Boeing)

2015 Milestone: 15,000 Shop Visits

Milestone at MTU Maintenance: 35 years after it was founded, the company celebrates the completion of its 15,000th shop visit. The engine in question is a CF34-10E, which was shipped to Aeroméxico Connect following overhaul at MTU Maintenance Berlin-Brandenburg. As an authorized service provider, the Ludwigsfelde location specializes in the CF34 and is also the first independent provider in the world that can support all versions in the engine family.

2017New location near Jasionka, Poland

In the fall, MTU Aero Engines and Lufthansa Technik reach an agreement to set up a joint maintenance company for Geared Turbofan™ engines, with each company holding 50 percent of the shares. The new location near Jasionka, Poland, is scheduled to start operations at the end of 2019 and will employ some 1,000 people over the medium term. Plans are in place to install enough capacity for the location to handle over 400 shop visits per year.

2018MTU Power

New member of the MTU family: With the new MTU Power brand, the company pools its gas turbine expertise from Aero Solutions, brush seals and MTU Maintenance. MTU Power offers the full range of services, from the development, design and manufacture of components and modules for OEM manufacturers to support for LM series stationary gas turbines derived from aircraft engines.

2018MTU Aero Engines Polska again expands its high-tech facility in Poland’s Aviation Valley

Groundbreaking for the next building expansion at MTU Aero Engines Polska: The facility increases its existing floor space by 11,400 square meters and boosts its headcount by roughly one quarter. The move is prompted by the tremendous advances made in the field of additive manufacturing technologies and the sharp increase in the MTU Group’s production rates. Of the total of 11,400 square meters of added floor space, 7,500 square meters are dedicated to production and 3,900 square meters are used to provide additional space required, as, for example, for production support activities.

2018NEFE: Safran and MTU Aero Engines join forces to develop the New Generation Fighter Engine (NGFE)

France’s Safran Aircraft Engines and Germany’s MTU Aero Engines will jointly lead the development, the production and the after-sales support of the new engine that will power the next-generation combat aircraft as part of the Franco-German Future Combat Air System (FCAS), which will enter into service by 2040. Under the partnership, Safran Aircraft Engines will take the lead in engine design and integration, and MTU Aero Engines will take the lead in engine services. MTU Aero Engines will be in charge of the low-pressure and high-pressure compressors and the low-pressure turbine, while Safran will be responsible for the combustor, the high-pressure turbine and the afterburner.

2019New repair facility in Serbia

MTU Aero Engines AG and the government of the Republic of Serbia sign a letter of intent with the aim of establishing a new company location in the Belgrade region. As one of the world’s largest MRO providers, MTU is looking to expand its existing network by adding a location dedicated exclusively to the repair of engine parts.

2019Answering tomorrow's challenges

At this year's Paris Air Show, the company is presenting its ideas and concepts for the future: evolutionary approaches for the next generation of engines as well as revolutionary concepts for the time after 2050. The goal is emission-free flying. The second GTF generation still offers significant potential and is to be further optimized to achieve even more serious emission reductions. The new engines should be in the air by the mid-2030s. In addition to these evolutionary developments, revolutionary propulsion concepts for the period after 2050 should also pave the way for emission-free flying.

2019MTU Aero Engines takes stake in the new hybrid-electric small aircraft

MTU Aero Engines is collaborating on the hybrid electric Silent Air Taxi, developed by e.SAT GmbH in Aachen, and its unique hybrid electric powertrain. The powertrain is being developed by e.SAT Powertrain GmbH, a subsidiary of e.SAT GmbH. The Silent Air Taxi is intended as a low-cost way to relieve the traditional main modes of transport that slashes individual travel times.

2019MTU Aero Engines AG joins the DAX

MTU Aero Engines AG joins the DAX, Germany’s leading share index, with effect from September 23, 2019. After 14 successful years in the MDAX, the company now ranks among the most important listed companies in Germany. MTU Aero Engines AG has been listed in the Prime Standard of the German Stock Exchange since June 6, 2005, and in the MDAX since September 19, 2005.

2020The coronavirus pandemic takes hold

The coronavirus pandemic has a stranglehold on global air traffic. At the end of March, MTU responds by suspending the majority of its activities at several European locations for three weeks and is forced to withdraw its guidance for the financial year. Operations gradually restart mid-April. Comprehensive measures are introduced to protect the health of employees. Efforts to minimize the impact of the pandemic continue. Liquidity reserves are expanded, and in July the company rolls out plans to adjust capacity by 10 to 15 percent by the end of 2021.

2020Kick-off for the fuel cell

Commercial aviation is committed to emissions-free flight. To this end, the German Aerospace Center (DLR) and MTU are collaborating to develop and validate a fuel-cell powertrain. At the beginning of August, the partners sign a memorandum of understanding (MoU) to develop a hydrogen-powered fuel cell with an electrical, single-sided propeller engine. A Do228 serves as the flight demonstrator.

2021European Military Engine Team (EUMET) is established

MTU Aero Engines, Safran Aircraft Engines and ITP Aero have agreed to jointly develop, manufacture and support the engine for the Next Generation Fighter (NGF). MTU is responsible for its flagship products, the high-pressure and low-pressure, compressor intermediate case, as well as for elements of the monitoring systems. Furthermore, MTU is the lead for all maintenance and service activities for the New Generation Fighter Engine within EUMET.

2021MTU sells Vericor Power Systems

MTU Aero Engines has sold Vericor Power Systems. The marine and industrial gas turbine (IGT) OEM, headquartered in Alpharetta, Georgia, USA, is being sold to the U.S. private equity firm CSL Capital Management of Houston, Texas, which focuses its activities on the energy sector. MTU had founded Vericor Power Systems in 1999 as a joint venture with Allied Signal - now Honeywell - and acquired it in 2002. Since then, the IGT specialist has been managed as a wholly owned subsidiary of MTU Aero Engines.

2021MTU Maintenance builds new site

At MTU Maintenance Zhuhai, the joint venture partners MTU Aero Engines and China Southern Airline Company Ltd. broke ground for the construction of a new site in Jinwan for engine disassembly, assembly and testing. The new facility will have an initial capacity of 260 store visits, will focus on Pratt & Whitney PW1100G-JM and IAE V2500 engines and will enter service in 2024. The site will run under the umbrella of MTU Maintenan-e Zhuhai and its licenses and permits.

2021MTU Maintenance Lease Services B.V. becomes a wholly owned MTU subsidiary

Amsterdam-based MTU Maintenance Lease Services B.V. (MLS), founded in 2014, has successfully established itself in the fields of engine leasing, asset management and technical consulting. MTU Aero Engines AG has acquired a 20 percent stake in MLS from Sumitomo Corporation. As a result, the company is now a wholly owned subsidiary of MTU. In the leasing sector, MLS focuses on short- and medium-term leasing business.

2021Improved Geared Turbofan

Pratt & Whitney will launch the Pratt & Whitney GTF Advantage™, a technologically improved geared turbofan (GTF) for the A320neo family. The GTF Advantage will reduce fuel consumption and CO2 emissions by an additional one percent each - improving the bottom line by a total of 17 percent each compared to previous generation engines. The GTF Advantage engine will be designed to run on 100 percent SAF when it is launched. All major components of the GTF core engine will be technically improved. In line with its program components, this means optimization work on MTU's high-pressure compressor and high-speed low-pressure turbine.

2022First use of sustainable fuel on the test stand

MTU Maintenance and JetBlue Airways are conducting acceptance tests with sustainable aviation fuels (SAF) for the first time at MTU's Hannover site as part of shop visits to the airline's V2500 engines. Initially, a fuel blend containing 10 percent SAF was used. It can be increased to up to 50 percent if required. This is the maximum limit currently permitted. The fuel used is sustainably derived from waste greases, oils and lubricants and produces up to 80 percent fewer greenhouse gas emissions per gallon over its entire life cycle than the conventional kerosene it replaces.

2022Three steps toward emissions-free flight

MTU is continuing its Claire technology agenda: It is guided by the Paris Agreement’s target of limiting the temperature increase to no more than 1.5 degrees Celsius. Whereas previous efforts focused on CO2 emissions, the scope has now been widened to include nitrogen oxides and contrails, because these factors together constitute the climate impact of aviation. MTU lays out potential solutions and concepts for sustainable commercial engines in Claire. Key elements are evolutionary enhancements of the gas turbine engine based on the geared turbofan, and completely new, revolutionary propulsion concepts, such as the water-enhanced turbofan and the flying fuel cell. Sustainable aviation fuels (SAF) and hydrogen play an important role.

2022SWITCH Project to Advance Hybrid-Electric and Water-Enhanced Turbofan Technologies

The Sustainable Water-Injecting Turbofan Comprising Hybrid-Electrics (SWITCH) project is focused on developing a novel propulsion concept built from two revolutionary and synergetic technologies: Water-Enhanced Turbofan (WET) and hybrid-electric propulsion. By combining these technologies with Pratt & Whitney’s GTFTM engine architecture, the SWITCH concept aims to significantly enhance efficiency and substantially reduce emissions across the full operating envelope of an aircraft. Technologies developed as part of SWITCH will be fully compatible with cleaner alternative fuels – such as Sustainable Aviation Fuel (SAF) — and will be evaluated for future use with hydrogen.

2023MTU acquires Starnberg electric motor developer eMoSys GmbH

With the acquisition of eMoSys GmbH MTU expands its global network to 18 sites worldwide. Together with eMoSys GmbH, MTU wants to accelerate the use of electric motors in aviation and develop them to market maturity. The collaboration will further strengthen the enterprising spirit and enormous innovative power of eMoSys, and the company will remain largely independent. The approximately 30-person eMoSys team has been working on electric motors for 35 years, and it is already active in the field of aviation as well as in other sectors. eMoSys GmbH was founded in Starnberg in 2013. The company has successfully been working with MTU for several years on a project basis. The parties agreed not to disclose the purchase price.

1970Launch of the new EU technology program HEROPS

The new HEROPS (Hydrogen-Electric Zero Emission Propulsion System) technology program for clean aviation was launched in mid-January 2024. It aims to build on MTU’s Flying Fuel Cell™ (FFC) to develop technologies for climate-neutral, hydrogen-powered electric propulsion that will get regional aircraft into the air starting in 2035.

The HEROPS industrial partners are MT Aerospace AG, RTX’s Collins Aerospace, Lufthansa Technik, and Eaton; the research partners are Netherlands Aerospace Center (NLR) and the Vienna University of Technology.

Led by MTU, the partners are planning to build a HEROPS ground demonstrator with an output of 1.2 megawatts over the project’s three-year term.

2024MTU Aero Engines celebrates its 90th anniversary

MTU Aero Engines has been at the forefront of the engine industry for nine decades. The next chapter in this success story will be engine concepts that enable emissions-free flight by 2050. The expertise and passion of its employees, their "Passion for Engines", have brought the company there and will continue to carry it into the future.

"90 Years and Beyond - Passion for Engines" is the motto under which the MTU Group is looking back on its history this year, but above all celebrating what makes it unmistakable: the passion and expertise of its employees for engines, for aviation.